Education

Instructors

Learning the art of glass beadmaking from an instructor will give you the skills needed to be successful in a variety of disciplines. These ISGB members are leaders in the field, and offer lessons to help you learn and grow as an artist. Look them up and start a conversation, they are all eager to share with you and help you on your journey.

If you are a glass beadmaking instructor and would like to be listed here, see our Call for Instructors below.

Perle di Vetro – Shelly Wollvin

Shelly Woollvin – Perle di Vetro private instruction available at Bay Area Glass Institute San Jose, CA, USA shelly@perledivetro.com perledivetro.com (805) 501-9575

Leslie Goldstein

PO Box 4418 Tumwater, WA 98501 http://lesliegoldstein.com

Sparkling Water Studios

Carolyn Collins- Santos 321 Shasta Dr Lodi, CA 95242 sparklingwatersstudio@yahoo.com http://www.sparklingwaterstudio.com

Tinker Bell Arts – Victoria Belz

Victoria Belz 227 S. Third Street, Suite 108 Geneva, Illinois 331.203.5162 http://www.tinkerbelzart.com

Lori Riley Dichroic Glass Designs

Lori Riley Dichroic Glass Designs http://www.loririleydesigns.com/

High Volume Oxygen, LLC

High Volume Oxygen, LLC 500 W. South Street, Suite #4 Lincoln, Nebraska 68522 (402) 476-0555 Office Make your own oxygen for less. https://www.highvolumeoxygen.com/

Elsie Kaye Glassworks

Holly Kenny, owner Elsie Kaye Glassworks art studio & boutique classes * gifts * home decor 3 Union St. Suite 2 Westborough, MA 01581 (508) 329-1605 elsiekayeglassstudio@gmail.com www.elsiekaye.com

Glass Mermaid Studio

Lisa Blanchard Glass Mermaid Studio Freeport, Maine 207-841-5947 glassmermaidart@gmail.com

Kristina Logan

Kristina Logan Portsmouth, NH 03801 kristina@kristinalogan.com

Malcom Potek

Malcom Potek Potekglass Minneapolis, MN USA 612-281-7243 info@potekglass.com

Flame Dame Glass Supply

Puala De Rienzo Flame Dame Glass North America’s largest Lauscha dealer. We also have a huge Supply of CiM and other 104 glass and are now expanding into 96 COE glass and frit. https://flamedame.com paulad@flamedame.com phone 941 -830 1595

Tin Roof Studios

E Susan Chambers Oklahoma

Melanie Rowe

Melanie Rowe Canada

Bronwen Heilman Art Glass & Glass Academy

Bronwen Heilman Art Glass & Glass Academy Bronwen Heilman Tucson, AZ Bronwen@BronwenHeilman.com http://www.bronwenheilman.com

Julie Anne Denton

Dr. Julie Anne Denton Zurich Glass School Zurich, Switzerland Contact info: +41 76 443 6931, info@julieannedenton.com

Terry Henry Glassworks

Terry Henry Terry Henry Glassworks Atascadero, CA /USA 559-361-6880 terryakhenry@gmail.com terry-henry-glassworks.com

Studiozero-vetro

Studiozero-vetro di Caterina Zucchi via Borra 33 57123 Livorno -Italia- p.i 01471120491 cell. +39 3488738717 Website www.studiozerovetro.it Instagram caterinazucchi

JMBGLASS – Marta Bernbaum

Josh and Marta Bernbaum JMBGLASS Brattleboro VT 802-254-4225 jmbglass@mac.com

Beads By Design

Stephanie A. White 585 Cobb Parkway S. suite L Marietta, GA 30060 770-425-3909 WWW.beadsbydesign.US

Glint

Heather Longacker Glint Glassworks Studio 10 Washington Street Ballston Spa, Ny 12020 Website: https://www.glintglass.com Instagram: https://www.instagram.com/heatherlongacker/?hl=en

Andrea Symons

Andrea Symons Molten Studios Squamish, British Columbia, Canada 604 698-5502 andreabeads@gmail.com www.andreasymons.com

Sabine Nuesch

Sabine Nuesch Victoria, PE victoriasglasstudio@hotmail.com

Elizabeth Morris

Elizabeth Morris Nottingham, NH opy145@yahoo.com

Patricia Zabreski Venaleck

Patricia Zabreski Venaleck Macomb, MI pzvglass@comcast.net http://www.pzvglass.com

Andrew Jackson Pollack Design

Andrew Jackson Pollack New Orleans, LA (504) 723-8235 andrewjacksonpollack@hotmail.com http://www.andrewjacksonpollack.com

Liliana C. Glenn

Liliana C. Glenn Natick, MA liliana@lilianabead.com http://www.lilianabead.com 617-821-2964 (leave voicemail)

Zealousbeader

Andi Abernathy Midlothian, TX Glasscanvasbeads@aol.com https://www.facebook.com/pg/GlassCanvasDesigns/

Artmosphere Studio

Michelle Pearson Anchorage, AK mpearson29@yahoo.com http://www.artmospherestudio.com

Dream Fire Glass

Dream Fire Glass Nina Sam Hibler San Antonio, TX dreamfiresam@gmail.com http://www.dreamfireglass.com/

Glacier Glass

Betsy Valian Government Camp, OR (503) 272-3525 vb53@centurytel.net

Call for Instructors

ISGB includes members and non-members in the Instructor listings.

To be included in the listing, please email the following information to our Operations Manager at operations@isgb.org:

- Your name

- Your studio/business name (if needed)

- Your city, state/country

- Your contact information (phone number, email address)

Professional Level or above ISGB Members also receive:

- Link to your website or social media page

- Photo to help showcase your business

If you would like a link to your website and you are not an ISGB member at that level, we invite you to join us!

Teaching Resources

Recommended Teaching Standards for Beginning Beadmaking Classes

Glass beadmaking is enjoying an enormous rise in popularity in the United States and internationally. What was once an art form, requiring an apprenticeship of many years to learn closely guarded techniques and color formulas, is now a popular, openly shared passion, being taught by glass beadmaking enthusiasts all over the world.

Unfortunately, there are no “industry standards” that specify what a good beginning beadmaking class should include. To this end, the Educational Resources Committee of the ISGB has developed an Instructor’s Seminar, which is presented each year at its international convention, The Gathering. Current issues in beadmaking instruction are discussed, and participants receive a resource notebook with curriculum outlines, student handouts, and current safety, glass and tool information.

Members of our committee have pooled their knowledge and many years’ experience as instructors, to develop guidelines that we hope will set a standard (and perhaps, raise the bar) for beginning beadmaking instruction. We want to give the prospective beadmaker insight into what you should expect to learn in a comprehensive course in beginning beadmaking. We have developed a set of questions for the beginner to ask of potential instructors / class sponsors. Making glass beads is about more than getting a round bead with dimpled ends: Proper training in safety, studio set up, equipment and glass chemistry are also important factors in creating beautiful (and durable) art glass beads.

Your beginning class may be the most important class you will take as a beadmaker. Remember that you may be a beginner, but you are also a consumer. Don’t be afraid to ask questions, and make sure that the money you invest in instruction provides you with all the necessary information you will need to go home, set up a safe workspace, and make beautiful beads!

- Ann Scherm Baldwin

Before you begin -

Consider first your goals for the type of beadmaking class you want to take:

Do you already know that beadmaking is something you absolutely want to do? In that case, you will want to look for a comprehensive beginning class that gives you a good grounding in safety and technique over the course of several days. With a knowledgeable and experienced instructor, this type of class is the wisest investment of time and money you could make. But some people aren’t quite sure if beadmaking is going to be their “cup of tea”…

It could be that what you want first is a quick overview of the safety issues, costs and equipment involved, and the experience of making a few beads. If you aren’t sure that you want to commit the time and money to beadmaking, this type of class can give you a feel for whether you like it, are good enough at it, and feel comfortable enough to pursue it further. This is what we call an “Introduction to Beadmaking”.

An introductory class can be accomplished by 3 – 4 hours of one-on-one instruction with a knowledgeable teacher, or a full day (6 – 8 hours) in a class with other students. Regardless of whether you get your introduction to beadmaking individually, or in a class with others, you should try to find an experienced instructor who will cover basic safety information about the torch, equipment and proper handling of the fuels/gases that you will be using. However, please understand that a three to six hour introductory class is not an adequate substitute for a comprehensive beginner’s class.

Once you’ve taken an “Introduction”, it’s very possible that you’ll join the ranks of the glass obsessed: you won’t be able to stop thinking about melting glass, you’ll find yourself making beads in your head before you drift off to sleep at night, and you’ll be considering where to set up your torch. Now is the time when you need to start looking for a comprehensive course in beginning beadmaking: Do this before you set up your beadmaking studio - you’ll receive lots of useful information in a comprehensive class that can help you make safe and appropriate equipment and set-up choices based on your individual situation.

Questions to ask about a Beginning Beadmaking Class -

Take the time to do your research, and don’t be afraid to ask questions. Here are some of the questions you can and should ask the teacher or group sponsoring the class:

* Who is teaching the class?

* How much experience does this instructor have?

Not all well-known beadmakers are great teachers, and not all great teachers will be particularly gifted beadmakers. However, a beadmaking instructor should have sufficient knowledge and technical proficiency in making beads to allow them to answer any questions a beginner will have. This includes guiding students through understanding the all-important safety issues, basic beadmaking techniques, the physical and chemical properties of glass, using and maintaining your equipment and setting up a beadmaking studio, based on their knowledge of and experience with hot glass.

Unfortunately, it’s difficult to measure a person’s beadmaking experience in months and years, because not many people make beads as a full time job. Gaining experience in hot glass is a cumulative exercise; advanced skill levels and understanding are reached only after many hours of continuous practice. This is why someone who makes beads for a couple of hours on weekends for three years might not have achieved the proficiency and skill level of another beadmaker who devotes 20+ hours a week, but has only been doing it for a year. So, although there will always be exceptions to the rule, a good rule of thumb regarding how much experience a beadmaking instructor should have is at least two to three years’ experience in making beads, before teaching others.

No matter how gifted a teacher someone is, or how kind and patient they seem, where beadmaking instruction in concerned, there is no substitute for being taught by someone with actual long-term experience creating beads out of hot glass.

Helpful questions to ask when looking for a qualified instructor:

Ask how long your instructor has been working in hot glass, and whether or not that’s full time, part-time or just as a weekend hobby.

Ask how long they have been teaching.

Ask who the instructor has studied with, or taken beadmaking classes from.

Ask to see pictures of the instructor’s beads.

Ask if the instructor has attended the ISGB Instructor’s Seminar. (And if not, please suggest that they do so!)

Ask for recommendations of good instructors from other beadmakers.

* How many hours of instruction will you receive?

A comprehensive beginning beadmaking class should be no less than 12 hours of instruction,regardless of whether that is over the course of several days or evenings, or in two consecutive days. Listed below is a basic outline of what should be covered in a beginning class. Even if you are receiving individual instruction, it is just not possible to cover everything you need to know about safety, equipment, glass properties, annealing and technique in a few hours time, and still allow time for questions, adequate supervised practice at the torch, and feedback for all the students from the instructor.

* How many people (at most) will be in the class?

For safety’s sake, there should be no more than 6 people in a beginning class with one instructor. If there is an experienced teaching assistant there to help supervise students when they are working on torches, the number of students should still be no more than 10. Regardless of how good a teacher is, a room full of beginners who have never worked at a torch with hot glass need to be carefully supervised, for everyone’s safety.

* Will there be a torch for every student?

Part of what you want to get out of a beginning beadmaking class is time on a torch. In a 12-hr class at least 4 to 5 hours of that should be spent on a torch. If not enough torches are available to go around, then the class should be longer to make up for this fact. Each student should get at least 4 hours of practice time on a torch.

* What type of torch will you be learning on?

There are generally two types of torches used to teach beadmaking: a single fuel torch, (such as a Hothead, Fireworks, or Quiet torch), and a mixed gas (propane/oxygen) torch (such as the Minor Bench Burner, Carlyle mini, GTT Bobcat, or others). A single fuel torch generally uses MAPP gas (or propylene) and does not require a major commitment of money or space to use it. It is however, noisy, can produce soot in the glass if not used properly, and melts the glass more slowly than a mixed gas torch. This is often considered a benefit for a beginner, because it will mean more control over the glass.

A mixed gas torch uses propane as the fuel, and oxygen as an oxidizer, which produce a very hot, quiet, adjustable flame. This type of torch does require a permanent set-up and a greater outlay of money for equipment and supplies. Both torches are fine to learn on; however, if you wish to get into beadmaking as a full time occupation, you will probably be investing in a mixed gas torch sooner or later, and may prefer to learn on one initially.

* Does either the instructor or the class sponsor carry liability insurance?

When appropriate safety precautions are taken, glass beadmaking is no more dangerous than driving a car. However, you wouldn’t want to be traveling along a highway surrounded by Driver’s Ed cars with learners behind the wheel, none of whom carried insurance, would you? In all probability, nothing bad will happen…. Right?

The risk might be slight, but the danger is no less real.

At this point in time, instructors in the beadmaking community are starting to realize the importance of carrying liability insurance, in order to protect themselves and their students should an accident happen. Unfortunately, it can be very costly, and in some circumstances, not available to everyone who teaches. Thus it is usually the exception rather than the norm. The ISGB is attempting to address this issue for instructors, but we’re still looking for workable solutions.

In a perfect world, every instructor or sponsoring organization would carry liability insurance against any accidents that might happen in a room full of beginners, working with hot glass and open flames. In reality, you may have a hard time finding an instructor who carries this type of insurance. (But that doesn’t mean you shouldn’t ask!)

It is our hope that liability insurance will become more reasonably available soon, and that having it before starting to teach will become an accepted practice for all instructors and teaching venues in the not too distant future. Liability insurance is a good investment to protect all parties involved in a beadmaking class.

Your safety is your responsibility:

It is up to you to weigh the risks and do what feels most comfortable to you.

Recognize that you may have to travel some distance to receive proper instruction in making glass beads. It’s better to wait and plan to take a safe and comprehensive class from a knowledgeable instructor, that will give you what you need to start your journey as a beadmaker, than to waste time and money on an incomplete, frustrating or dangerous experience.

And a few other questions that you may also want to ask:

Does the cost of the class cover all the materials, glass, supplies and equipment you will be using?

Will a class outline be distributed, so you can concentrate on watching the instructor demo, rather than taking notes?

Will there be any supplemental handouts or reference materials given to you at the end of class?

Will your beads from the class be annealed; How / when will you get them?

Once glass has been melted, it needs to “soak” at a certain temperature for a specific amount of time, and then be cooled slowly in a precise manner only possible with a kiln. This is just not possible using a fiber blanket or vermiculite. If your beads from class have not been annealed during the class, it is often possible to “batch anneal” them later, but some of them may crack or break due to unrelieved stress in the glass.

Classroom safety issues -

What constitutes a “safe” beadmaking class environment?

* Ask about the actual classroom space where your class will take place:

There should be adequate ventilation for the size of the room. Proper ventilation requires three things: A way to remove stale air or fumes from the work area (preferably vented to the outside), clean make-up air brought into the work area, and a method of keeping the air circulating in the room. A fan and an open window are not sufficient if there are several torches turned on at the same time. All torches pull oxygen from the air for combustion, exhausting the room’s fresh air supply more quickly and release harmful combustion gases that can build up in a poorly ventilated workspace.

*Without proper ventilation, after a long day hunched over a torch, you might experience headaches, dizziness, tightness in your chest, and other mild, but worrisome, symptoms. If so, turn off your torch, tell the instructor, and go outside for some fresh air.

Every student should be provided with proper safety glasses: Clear plastic “science class” goggles or sunglasses will protect your eyes from flying glass but not from the potentially damaging light coming off the flame and the hot glass. Student safety glasses should have a rose didymium or stronger filter on the lenses. (The lens will be dark purple/gray.)

The workspace near the torches should be clear of flammable/combustible materials, because flying chips of hot glass can travel a good distance.

Torches should be securely attached to the tabletop, and matches, flint strikers or electronic arc lighters should be provided for lighting the torch. (Not butane lighters.)

The floor and tabletop should be heatproof. (Metal or tile, etc.)

The instructor or class sponsor should let you know ahead of time about appropriate clothing safety issues: Long hair should be tied back, you should wear long sleeved, cotton or natural fiber clothing (polyester melts; need we say more?), and no shorts, plunging necklines or open toed sandals… just in case. Long artificial nails can sometimes pose a hazard for beginners.

ISGB Beginning Beadmaking Curriculum -

ISGB Recommended Course Outline:

What should be covered in a Comprehensive Beginning Beadmaking Class:

This list includes the idealinformation a beginner should have before setting up a studio and working alone. Not all classes will include every single item covered here, however safety and equipment use should be a top priority, and covered in detail.

Please note that this checklist indicates safety information when setting up a studio with a minor or other mixed gas torch. Necessary information for working with a hot head torch is listed in brackets.

1. SAFETY!

- Handling tanks and gases safely - Propane tank outside, Oxygen tank secure

- {Working with MAPP or propylene gas; safe handling of bulk tanks as well as canisters}

- Setting up a safe workspace, torch securely fastened to the table

- Eye protection, appropriate clothing for flame work

- Proper Ventilation – Remove, Replace, Circulate

2. Equipment

- Using & maintaining gas tanks, hoses, safety features & regulators

- Different gas options & Oxy concentrators

- Torches; Order of turning on the gases and lighting the torch

- Shutting down the equipment when done

- Kilns – proper kilns for annealing beads, digital controllers

- Cooling with fiber blankets and vermiculite & the limitations of these methods

- Batch annealing

- Basic tools used in beadmaking

3. Ergonomics

- Proper way to hold mandrels and rods and optional handles to make gripping easier

- Importance of good posture, taking breaks and using armrests

- Workbench set up: Chair on wheels, good lighting, table height

4. Physical and Chemical properties of glass

- Different types of glass (hard glass, soft glass, different brand names)

- COE and compatibility

- Stress in glass, thermal shock

- Annealing, annealing range, annealing point, and strain point

- Importance of understanding glass and heat – glass is a poor conductor of heat

- Reduction flame and oxidizing flame

- Effects possible using different colors of glass & flame chemistry

5. Beadmaking basics

- Avoid thermal shocking rods by warming slowly, perpendicular to the flame

- Winding glass on, laying down an even “footprint”

- Importance of slow, even rotation of mandrel

- Positioning of the hands

- Adding extra glass

- Where to work in the flame

- Using heat and gravity to help shape the bead

- Making even and dimpled ends

- How to remove air bubbles

- Shaping with graphite tools, making different bead shapes

6. More techniques

- Pulling stringer

- Decorating with fruit

- Making two color twisties, cased stringer

- Making dots, twisting dots, layering dots, feathering and raking

- Distorting the surface of a bead: poking, squashing, raking, twisting, cutting, etc.

- Applying canes and stringer

- Applying murrine

- Basic encasing

7. Preparations and clean up

- Preparing mandrels from welding rods

- Proper consistency for bead release, how to dip mandrels, and dry release

- Cleaning glass rods

- Removing beads from the mandrel

- Cleaning bead holes

8. Resources

- Recommended reading or video viewing

- Information on suppliers of glass, tools, and equipment

- Information about the ISGB and other bead & glass related organizations

- Questionnaire handed out to provide feedback to the instructor

Copying and Artistic Integrity

A Few Words of Wisdom for Teachers and Students:

The Role of Copying and Artistic Integrity in the Classroom

Copying

Copying and repetition are an integral part of the learning process. Don’t be afraid to take what your instructor has demonstrated in class, and practice, practice, practice it at home. Instructors shouldn’t be demonstrating any techniques that they don’t want their students copying; nothing learned in class should be off limits to the students who paid for the instruction.

Artistic Integrity

Once you set up your studio and start making beads in earnest, it’s important to try to begin to “find your own voice” in the beads you make, and not continue to copy the exact beads that you have learned from your instructor. When you have a bead that you really like, but you have learned from someone else, try to assess what it is that appeals to you about it, and then take that idea, technique, or color scheme, and play with it.

A common occurrence in beadmaking classes is students bringing in beads that they are intrigued with, to ask their instructor how a certain look was achieved. If the technique is a simple or common one, most instructors will be happy to demonstrate, if time permits. Please respect the artistic integrity of other beadmakers, and don’t ask your instructor to speculate or show you how another beadmaker achieves something that makes their work uniquely their own.

The roles of Instructor and Student in a Beginning Beadmaking Class -

The role of the instructor:

- The instructor should be in the room with students at all times while torches are running.

- The instructor should circulate around the room while students are working on torches, giving feedback and assistance to the students.

- An instructor should never be working on his or her own beads while students are practicing; receiving feedback from an experienced teacher is an important part of the learning process.

- The instructor should explain what they are doing as they demonstrate, repeat instructions patiently when necessary, offer helpful suggestions and critique in a positive manner, and affirm the students efforts. Learning to make beads should be an exciting, satisfying experience for every student.

- Instructors should not allow any one student to monopolize the class or their time.

The role of the student:

- Students should be on time to class, and return from breaks punctually.

- Be sure to dress appropriately for the class; Wear long hair tied back, natural fibers, and no excessive jewelry that might catch a flying piece of hot glass.

- It’s your responsibility to ask questions when you don’t understand something, and ask for clarification if you’re unsure. Don’t be afraid to ask questions!

- Please recognize that all the students in the class have paid to be there. Don’t monopolize the instructor’s time, or make small talk while the instructor is demonstrating, as it distracts others from what is being taught.

- If you are uncomfortable with a situation, or feeling unwell, please let the instructor know. Teachers can’t fix a problem they were never told about.

- Pay attention to others around while you work, and take extra precautions – you’re often concentrating so hard on beadmaking that you don’t watch where you’re putting down hot tools and glass rods, and due to space limitations of most classrooms, you will probably be fairly close to the person torching next to you.

- Be sure to utilize ALL the information that you’ve been given on safety when setting up your studio, even if it means added expense or inconvenience. Your health and well being are too important to risk doing otherwise!

Safety has always been important to ISGB and our members. Many beadmakers, beginning and others, have looked to ISGB for information about safety issues. It is with great pleasure that ISGB presents the information researched and developed by its Safety Committee. The information is formatted as an outline with an extensive bibliography following. Those resources can be found at Rakow Library at the Corning Museum of Glass.

Safety Committee Members: Mike Aurelius, Aura Lens; Bill Gilbert, Corning Museum of Glass; Vince Henley, ISGB safety forum and Glass Bead column; Elizabeth Hylen, Rakow Library at Corning Museum of Glass; Lisa St. Martin, ISGB Gathering class set up; Robert Simmons, ISGB Glass Bead column; Margie Shanahan, Director of Education and committee chair.

Additional thanks to the following for their input: Kendra Bruno, ISGB Executive Director; Nina “Sam” Hibler, ISGB Regional Director; Loren Stump; Jesse Kohl.

The following articles are available in PDF format, please select to download:

ISGB Eye Safety Outline and Bibliography

ISGB Fire Safety Outline and Bibliography

ISGB Personal Safety Outline and Bibliography

ISGB Respiratory Safety Outline and Bibliography

ISGB Ventilation Basics Outline and Bibliography

General Resources Studio Safety

NOx Emissions from your Torch

by Stan Wolfersberger

Many of the books on glass beads mention the necessity of ventilating your studio. Recent measurements made by me underscore this need. Using detector tubes, I measured levels of a number of gases while my wife made beads with a minor bench burner. The results suggest that NOx, rather than carbon monoxide, may be one of the chief hazards you face in your studio.

What is NOx? This is a shorthand notation for the mixture of nitrogen oxides, which are generated from many types of combustion. The level of NOx depends on many aspects of the combustion process, such as the fuel and oxygen ratio, temperature, etc. NOx is a known respiratory irritant. Propane-oxygen torches attain fairly high temperatures, yet the fact that oxygen is used rather than air for combustion would normally lead one to believe that NOx would not be emitted at high levels.

Part of my job involves performing air sampling and analysis to measure employee exposure to chemicals and irritants. Detector tubes are a fairly inexpensive means to obtain quick, reasonably reliable measures of many substances. Using a small, hand-operated pump, air is pulled through a tube, which is coated with a material that reacts with the substance of interest. A colored stain is formed that is proportional to the amount of the substance present in air. Different tubes are available for many substances.

While Pamela made beads, I used detector tubes to measure the levels of carbon monoxide, carbon dioxide, and NOx in the room. Carbon monoxide was not detected under any condition. Carbon dioxide, while elevated a bit from ambient levels, was not at levels that would cause concern. However, NOx levels exceeded 15 parts per million in air (PPM) on numerous occasions. Even with considerable ventilation, NOx was ALWAYS at levels above 1 PPM.

What does this mean for you? Pamela's current studio is our spare bedroom, which has a single door and window. I have experimented with a variety of fan placements, and so far, I have not found a combination that effectively eliminates the NOx. Unfortunately, complaints of "that fan is blowing my flame" mean that you may be settling for less ventilation than is needed to remove emissions from your torch. We have purchased an overhead fan (like the ones required in bathrooms in new construction) to try and remove more air without disturbing the flame significantly. We'll let you know how this works out.

I'll continue to research this. I discussed what I found with the NIOSH folks who were at Corning. However, they did not bring the equipment to do NOx testing while at Corning, so don't expect any revelations from them short- term. It would be very desirable to get data on other equipment (different torch models, fuels, etc.) to see if this problem is equally severe for all glass bead makers. I hesitate to make broad statements based on measurements from a single torch set-up, but the levels of NOx I found WERE SO SURPRISING that caution is in order. If your family, friends, etc. come into your studio and remark on the odor, this is an indication your ventilation is probably not adequate.

1998 NIOSH Beadmaking Health Hazard Evaluation

In 1998, NIOSH conducted a health hazard evaluation at the Society of Glass Beadmakers (SGB) annual convention in Corning, New York to look at eye exposures to various types of optical radiation and chemical exposures to substances during glass beadmaking demonstrations.

You can see the report here:

Highlights of the NIOSH Health Hazard Evaluation - Exposures During Glass Beadmaking

Show Preparation and Participation Outline

This Outline was developed out of a need to have a document for mentors to use with Student members who are new to bead shows such as the Bead Bazaar at the ISGB annual conference, the Gathering. It has evolved into a document that any member who participates in shows will find useful. Susan Matych-Hager’s original outline, which was used in presentations to college art classes for students who wanted to participate in art shows, was used as a basis for this Outline. It has been refined and expanded by the following members of the ISGB Student Outreach Committee: Susan Matych-Hager, chair; Margie Shanahan; Allison Johnson; Kendra Bruno; and Hayley Tsang Sather.

A PDF copy of the outline may be downloaded HERE.

Beadmaking Presentation and Demonstration Outline

This Outline was developed in response to requests from ISGB members who have been asked to demonstrate glass beadmaking. Margie Shanahan’s original presentation, which she has used for a number of years when demonstrating for high school art classes and adult art groups as well as other organizations, is the basis of this Outline. It has been refined and expanded by the following members of the ISGB Student Outreach Committee: Susan Matych-Hager, chair; Margie Shanahan; Allison Johnson; Kendra Bruno; and Hayley Tsang Sather.

A PDF copy of the outline may be downloaded HERE.

Visit our YouTube Channel for Tutorials and Lessons for all skill levels

Tutorials

The ISGB is a community of members who often inspire each other to grow. These FREE tutorials are provided courtesy of the ISGB and many can be found in our quarterly publication the Glass Bead Evolution.

We invite you to join us!

Beth Williams has developed a technique working with color pencil on glass. This is the tutorial from the Glass Bead Evolution Volume 7 Issue 3. A challenge was initiated at the 2019 Gathering to be on exhibit at the 2020 Gathering.

Enjoy these Free Tutorials for inspiration when creating for Beads of Courage

Turtle Tutorial by Jelveh Designs

Little Ghosties Tutorial Karen Crown

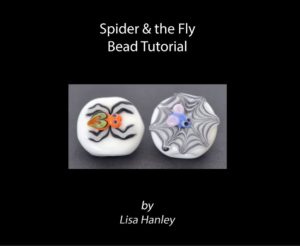

Spider Tutorial by Lisa Hanley

Wolf Cube Tutorial By Kari Chittenden

Puppy Tutorial by Marcy Lamberson

Special Requirements: Act of Courage Beads

Act of Courage Beads can take almost any form that you would like to make—it’s an opportunity for you to let your imagination go! The 3/32″ mandrel is preferred but other sizes are also usable.

Please have nice ‘puckers’ on the ends of the beads, sharp edges on the bead holes cut fingers and cannot be used. Overly frilly bits sticking out may break off and leave sharp edges on the surface, be sure that raised dots have solid connections (no undercuts) and that surface decorations are robust enough to take some knocking about.

We ask that you refrain from using reduction frit or glasses that give a metallic sheen on the surface due to heavy metal issues with these materials. We can’t send metallic reduction surface beads to the kids.

Anneal your beads properly in a kiln to ensure they don’t crack. Cracked beads have to go in the waste basket.

Please make sure that the bead release is cleaned out. Beads with the release still inside take more time for our volunteer staff to clean and this tremendously slows down turnaround time to the hospitals.